Availability As Early As The First Week Of December

Buying & Selling

Level-2 camera/video inspections for the purpose of buying or selling a home is not a provided service. Notice to realtors: I am not available for hire, as I only provide service to the private homeowner.

Mt Freedom Chimney is a small, service-focused company, and large repair projects aren't taken on. Since the purpose of an inspection is to assign a dollar amount towards necessary repairs and aid in negotiating a credit amongst the buying and selling parties, it would be disingenuous of me to establish an appointment, knowing I'm unable to provide itemized repair estimates. Company policy is only the legal homeowner is eligible for services, and sellers may contact me for information or and appointment. The below information is intended as a convenience to curious homeowners (or home buyers) to better assist as buying and selling are already stressful enough.

Parties seeking to purchase a house should consult with a larger, repair-based chimney company. The average age of a house in our corner of northern New Jersey is a little over 50 years, putting your new home roughly into the 1970s for initial construction. New Jersey adopted the ICC's International Residency Code (IRC) in 1996 as its statewide uniform standard, to which, under N.J.A.C 5:23, grandfathering is [relatively] no longer permitted. A general recommendation to sellers is to amend your listing to reflect the wood-burning application(s) of you chimney(s) as "as is," as in New Jersey it is not permissible to label solid-fuel appliances as a primary heat source (wood, coal, pellet). Permitted main heat sources are class-2 diesel (oil), natural gas (NG), propane (LP), and electric; open-faced fireplace applications cause a net-negative energy loss, and should never be considered as a contingency when a home loses its capacity to use home-heating and hot water appliances.

Disclosing All Findings

Ex: Exposed Heating System Lining Above Fireplace

It's common practice for licensed chimney professionals to cite chapter and paragraph for building code deficiencies and violations. Observable building code violations will be documented and disclosed. This is to transfer liability to the home owner if the appliance is continually used post-servicing and inspection. Asking me to omit such findings or supplementary service and repair recommendations is unethical. Asking me to remit a second invoice stating only chimney sweeping was performed will not be humored.

If you're selling your house, I will definitely NOT humor the request of omitting defects and violations. The sale of your house will not be more easily facilitated at the expense of my company's liability. I take these requests as a great insult as it shows a complete lack of value in my work and my good standing. If you feel I'm not the right fit for your chimney service needs based on the above-mentioned, you're not the right fit for me as a customer.

Adoption of...

N.J.A.C.5:23 (1996)

New Jersey adopted the ICC's IRC as its, state-wide building code standard in 1996. Grandfathering is permitted for no greater than a 6 month period after the release of a new publication. The latest publication of "Chapter 10: Chimneys & Fireplaces" is January 2024. Code violations are cited/documented on invoices.

NJUCC - NJ Uniform Construction Code

N.J.A.C. 5:23

New Jersey adopted the ICC's IRC as its statewide, uniform standard for residential construction. There are 44 chapters and 10 appendices under the IRC that provide the minimum construction and safety requirements for all homes, new and old. The ICC frequently updates the IRC in rotating cycles about every three to six years, depending on chapter, and advances in construction technology. There are several more chapters which overlap regarding chimney usage and construction: chapters 17, 18, 20, 24, and 28; chapter 15 is related to dryer vents; chapter 9 is related to roof construction.

Grandfathering

New Jersey allows for a grace period no greater than six months before the latest edition of building code publication takes precedence. There is no appeal process to grant grandfathering at the state, county, or municipal levels - and historic structures are not exempt from fire sub-code/fire safety. The current edition of I.R.C. Chapter 10 "Chimneys & Fireplaces" is 01 January 2024. The overwhelming majority of the codes in Chapter 10 were standardized in 1994, two years prior to New Jersey's adoption. Chimney-specific repairs for code compliance can't be enforced until selling a home, or performing a fuel conversion (wood-to-gas for fireplaces; oil-to-gas for heating systems). This includes appliance replacements, such as installing a new water tank (natural gas or propane).

Permits

Aside from the legal property owner(s), only a New Jersey licensed contractor, HIC or otherwise, may apply for permits; all contractors are required to furnish proof of licensure and commercial general liability insurance to municipal building departments (N.J.S.A. 56:8-142). Mt Freedom Chimney's license number is NJHIC 13VH06466100. New to 2025, all HIC licensees must be bonded. Workers comp is a required insurance for W-2 employees; controlling interests of 10% or greater are permitted to use their personal health care coverage. All chimney lining installations require permits to be issued from the municipality where a worksite is located; new and replacement appliance installations which vent exhaust into a chimney also require permits: heating systems, water tanks, fireplace inserts, wood stoves, new fireplaces, oil-to-gas conversions, wood-to-gas conversions.

R1003: Chimney Construction

R1003.12: Flue Lining

The most frequently occurring reason for new chimney liner installation is R1003.12, found in Chapter 10 "Chimneys & Fireplaces" under the IRC. Conventional cement (sand-mortar mix) joints are not water-insoluble, and will become loose, sandy, and gritty over the years, and will eventually fall out. This will lead to gaps and openings between clay flue tiles at two-foot iterations. If the chimney structure undergoes thermal shock (chimney fire), conventional cement joints are "blown out" due to not being made from high-heat rated refractory material. Soot and flammable creosote will be able to circumvent flue tiles, and become trapped in the air spaces between the chimney's outer shell and interior flue liner, rendering basic chimney sweeping all but useless for preventing future chimney fires. Regardless of condition, when converting fuel types (wood-to-gas for fireplaces and oil-to-gas for home-heating systems), liner installation will be required. This includes appliance replacement for similar fuels (changing out a hot water tank). Municipal building departments now issue a "chimney verification certificate" in plumbing permits, to which your plumber or HVAC company will have to submit once a chimney inspection has been performed. If chimney "relining" is required, a separate permit from your town is required in conjunction with fuel conversions and appliance replacements. Chimney "relining" is the standard repair solution when the above-mentioned building code is in violation. It is also the most commonly occurring chimney repair, being able to correct such issues as flue decay/deterioration, shifted/misaligned flue tiles due to settling, and absences of an original lining due to incorrect or predated home construction.

R1003.1: General

Interpreted under R1003.1, painting a masonry chimney's exterior surface is one of the worst things a home owner can have done. All masonry is porous, and will absorb water and precipitation. This is especially important when located in the northeast, as there's no short supply of rainy springs, summer humidity, autumn hurricanes, and snowy winters. Paint acts as a sealant, and painted masonry will lose its ability to breathe when warm-weather temperatures would normally allow for the evaporation of internal moisture.

Additionally, the chemical process of combustion yields water and condensation within the exhaust mixture (especially for gas applications). Some fuel types have either a high or low condensation content; gas applications have the highest. When an adequate volume of trapped, internal moisture isn't able to breathe and evaporate, the chimney structure will undergo freeze-thaw damage over the winter into the spring. This may occur over just one year, but most times will take several years.

Aside from the unsightly polka-dot aesthetic, this will also compromise the chimney's structural integrity, and most times the corrective repair is a roofline-up or ground-up (and costly) rebuild. It is always recommended to have a painted chimney's surface sandblasted to remove paint.

Clearances

R1001.11

This paragraph outlines combustible trim and materials must remain a minimum of 12 inches above the fireplace opening. While the TV satisfies the requirement, electronics are sensitive to heat and smoke, and may still become damaged when suspended above or in front of a fireplace.

R1003.9: Minimum Chimney Height

Install Violations

Chimney sweeping is retracted, and an invoice with a service charge for an inspection will be remitted for the below examples stating the application is "unsuitable for use due to violations under ICC-IRC building code / NFPA standards and regulations / UL testing and compliance, and that continued usage may result in property damage or injury; and appliance usage should cease immediately until necessary repairs are completed." Liability for continued usage of such an application is transferred to the homeowner/property owner once full disclosure has been provided.

Install Violations

Unlined Masonry Fireplace with Insert-Stove

Factory-Prefab Fireplace with Free-Standing Stove

Unlined Masonry Fireplace with Insert-Stove

Both NFPA-211 regulation and IRC R1003.12 building code require this application to have a stainless, insulated chimney lining system installed throughout the entirety of the chimney height.

Factory-Prefab Fireplace with Insert-Stove

Factory-Prefab Fireplace with Free-Standing Stove

Unlined Masonry Fireplace with Insert-Stove

Not permitted under NFPA-211 regulation and IRC R1004.1 and R1005.1, as UL-1777 compliance for the lining system isn't achieved and UL-127 is violated according to both the fireplace and liner manufacturers.

Factory-Prefab Fireplace with Free-Standing Stove

Factory-Prefab Fireplace with Free-Standing Stove

Factory-Prefab Fireplace with Free-Standing Stove

Not permitted under NFPA-211 regulation and IRC R1004.1 and R1005.1, as UL-1777 compliance for the lining system isn't achieved and UL-127 is violated according to both the fireplace and liner manufacturers.

Prefab Fireplace with Pellet Stove or Insert

Prefab Fireplace with Pellet Stove or Insert

Factory-Prefab Fireplace with Free-Standing Stove

Not permitted under NFPA-211 regulation and IRC R1004.1 and R1005.1, as UL-1777 compliance for the lining system isn't achieved and UL-127 is violated according to both the fireplace and liner manufacturers.

Converging Flues

Prefab Fireplace with Pellet Stove or Insert

Converging Flues

Every appliance is required to have its own flue liner. Converging flues ceased pre-Civil War in the 1840s and 1850s. Converging flues create a syphoning effect, where exhaust will be pulled back down into a lower level of the house.

Mixed Fuel Types

Prefab Fireplace with Pellet Stove or Insert

Converging Flues

Oil home-heating systems sharing a flue with a natural gas or propane water tank is still permissible in most areas, but solid-fuel (wood, coal, pellet) appliances cannot share a flue with oil or gas home-heating appliances, under NFPA-211, NFPA-31, and NFPA-54.

Chimney Fires

While chimney fires may not cause damage to the surrounding areas of your home and you may think you've gotten lucky, the odds are against you for continual, safe usage. Masonry chimneys are required to use these two-foot clay "flue tiles" to line the interior; aside from thermal shock to these tiles, the cement joints at every two foot interval are blown out, and the chimney will require the installation of a stainless steel chimney liner system. All liner installs require permits.

Common IRC & NFPA Violations

R1001.5.1 - Steel (Heat-Form) Fireplace Units

Heat warping and cavitation; deterioration from age, rust, and wear. Absence of integral recirculation vent chambers will lead to excessive heat transfer beyond minimum clearances.

R1001.7 - Fireplace Dampers

All fireplaces are required to have a damper, which closes off access to the flue.

R1001.8 - Fireplace Smoke Chamber

Undersized or oversized in correlation to fireplace size and volume. Open and exposed brick surface, as the interior is required to be parged with a high-heat refractory mortar.

R1001.9 & R1001.10 - Hearth Construction & Dimensions

Hearths must be able to support their own weight, be constructed of non-combustible building materials, and be a minimum of 4 inches thick. Hearth extensions are to be at least 16 inches in length for fireplaces with openings under 6 square feet; at least 20 inches for 6 square feet or larger.

R1001.11 - Fireplace Clearances

Decorative wood trim, wood mantels, and anything combustible must remain a minimum of 6 inches away from the left and right sides of a fireplace opening, and a minimum of 12 inches above a fireplace opening.

R1003.1 & NFPA-211 - Chimney Exterior

Masonry chimney exterior surfaces cannot be sealed or painted, as this will trap internal moisture, causing freeze/thaw damage.

R1003.7 - Flue Lining Offsets

Flue lining offsets cannot exceed 30 degrees.

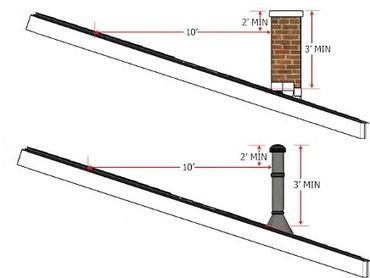

R1003.9 - Height & Termination

Chimneys must protrude at least 3 feet from where breaching the roofline; chimney height must be a minimum of 2 feet taller than the tallest point within a 10 foot radius. Chimney crowns must facilitate a drip edge. Spark arresting chimney caps are required.

R1003.9.2 - Rain Caps

Rain caps or spark arrestors have been required for all chimneys since IRC building code was first published.

R1003.12 & R1003.13 - Flue Lining Construction

High-heat, water non-soluble refractory mortar is the required jointing medium for every 2 foot section of clay flue lining, as conventional cement deteriorates in high-heat and high-moisture environments. Individual flue linings are required to be encapsulated by a minimum of 4 inches solid masonry, creating dividing walls. Converging flues whereas multiple appliances share one flue is not permitted.

R1003.14 & R1003.15 - Flue Lining Area & Dimensions

Minimum flue area is correlated to appliance size and dimensions; most common violation is the fireplace flue being undersized, which typically leads to weak draft and performance.

R1004.1 & R1005.1 - Factory Fireplace & Chimney Pipe Systems

Factory-prefab fireplace systems are UL-listed and tested for their factory configurations, and any alterations are not permitted (RE: wood stove or wood insert installations). Factory-prefab chimney pipe systems are UL-listed and tested for their factory configurations, and any alterations are not permitted (RE: aftermarket chimney liner installation and converging flues).

I.R.C Chapter 18 M1801.11 - Multiple Appliance Venting

All gas and liquid fueled appliances (natural gas, propane, oil) sharing a common chimney flue must be located on the same floor of the dwelling.

I.R.C Chapter 18 M1801.12 - Multiple Solid-Fuel Appliances

All solid-fuel (wood, coal, pellet, etc) appliances are must be vented individually into a flue, independent to all other appliances.

I.R.C Chapter 24 G2406.2 & NFPA-211 - Prohibited Areas

Appliances cannot be located bedrooms, bathrooms, or closets; solid-fuel burning applications, such as wood stoves, require a minimum of 5,000 cubic feet to satisfy air inlet/intake requirements.

I.R.C Chapter 24 G2406.3 - Outdoor Locations

Appliances located outdoors (to include sheds) must be rated and approved for outdoor location, with visible labeling.

I.R.C Chapter 24 G2428.3 - Appliance Connections

Multiple appliance connectors are not permitted to enter on the same horizontal plane. Lower-input rate appliance connectors must be positioned above higher-input rate appliance connectors for multiple input rate appliance convergences.

M1501.1 - Outdoor Discharge

Dryer vents aren't permitted to vent into open attic space or a garage.

M1502.2 - Independent Exhaust Systems

Dryer vents are not permitted to be paired with a duct from a different appliance, like a bathroom fan or kitchen stove draft hood.

M1502.3 - Duct Termination

Dryer vents aren't permitted to vent within three feet of any door or window opening. Screens are not permitted to cover the termination, but single-piece or multi-piece louvers are allowed, as they double as a back-draft damper.

M1502.4.1 - Duct Material & Size

Dryer vents must be constructed from 4" DIA smooth-walled, rigid pipe.

M1502.4.2 - Duct Installation

Rigid pipe sections are not permitted to be fasten with screws.

M1502.4.3 - Transition Duct

Flex pipe connecting the dryer appliance's breach and rigid pipe cannot exceed 8 feet, and are not permitted to be concealed within walls.

M1502.4.5 - Duct Length

The maximum dryer vent length is 35 feet. For every 45-degree offset in the lateral, two and a half feet is subtracted from the max length. For every 90-degree offset in the lateral, five feet is subtracted from the max length.